The ECOAZUR® System

A complete sustainability solution

High-performance technology that taps into hidden opportunities

IRIS BLEU® OPTICS

What they do:

These sensors measure the emission of smoke, vapor, or fumes and increase the exhaust rate only and as much as necessary.

- Allows for the widest airflow modulation range

- Waterproof, impervious to grease (no air purge units)

- Requires little to no maintenance

MODULATING DAMPERS

What they do:

In situations where multiple hoods share a common exhaust fan, ECOAZUR® modulating dampers help to independently control the exhaust rate of each hood, regardless of the number of hoods connected to an exhaust system – thus improving overall kitchen performance

- Quick reaction time (4 s)

- Open fail-safe position (fire, VFD in bypass)

- Easy to install in new or retrofit applications

- No cleaning, cutting or welding duct work required

SECURED CLOUD PLATFORM

What it does:

This easy-to-use web platform informs your management team that maintenance and operations are aligned with your ROI target. It also provides access in-depth analytics and reports that will allow your team to gain insight into how to optimize your ventilation and benchmark your kitchen’s performance.

- Remote monitoring

- Simple dashboard

- Email notification

See how it works

ECOAZUR® Primary Components

Using our proprietary communication protocol offers a versatile sensor network topology:

- Automatic detection/addressing of ECOAZUR® intelligent sensors

- User-friendly RJ45 connections limit wiring errors

- ECOAZUR® network hubs minimize cable lengths

Hood sensor network components may include:

- Optic sensors (IB) – located in the hood canopy

- Temperature sensors (TT) – located in the hood canopy and/or the hood collars

- Pressure sensors (PT) – located in the exhaust ducts and/or behind the hood plenum

- Network hubs (NE) – located above the hood

- User interface (CT) – one or many keypads may be installed throughout the kitchen

- Digital input modules (DS) – panel mount, signal coming from a third-party device

- Analog input modules (AS) – panel mount, signal coming from a third-party device

- Network cables (NF) – designed specifically for the hood environment, RJ45 connectors

Processor Panel components include:

- ECOAZUR® Processor (CU)

- ECOAZUR® Output Module(s) (TC)

- Power Supply (120-240Vac to 24Vdc)

- Light Control Relay

- Cloud Module (optional)

The ECOAZUR® Processor Panel interfaces to ventilation equipment and third-party devices such as:

- VFDs, ECMs and/or ECOAZUR® Modulating Dampers

- Fire Suppression System

- Hood Lights

- BAS inputs/outputs

- Kitchen temperature sensor (optional)

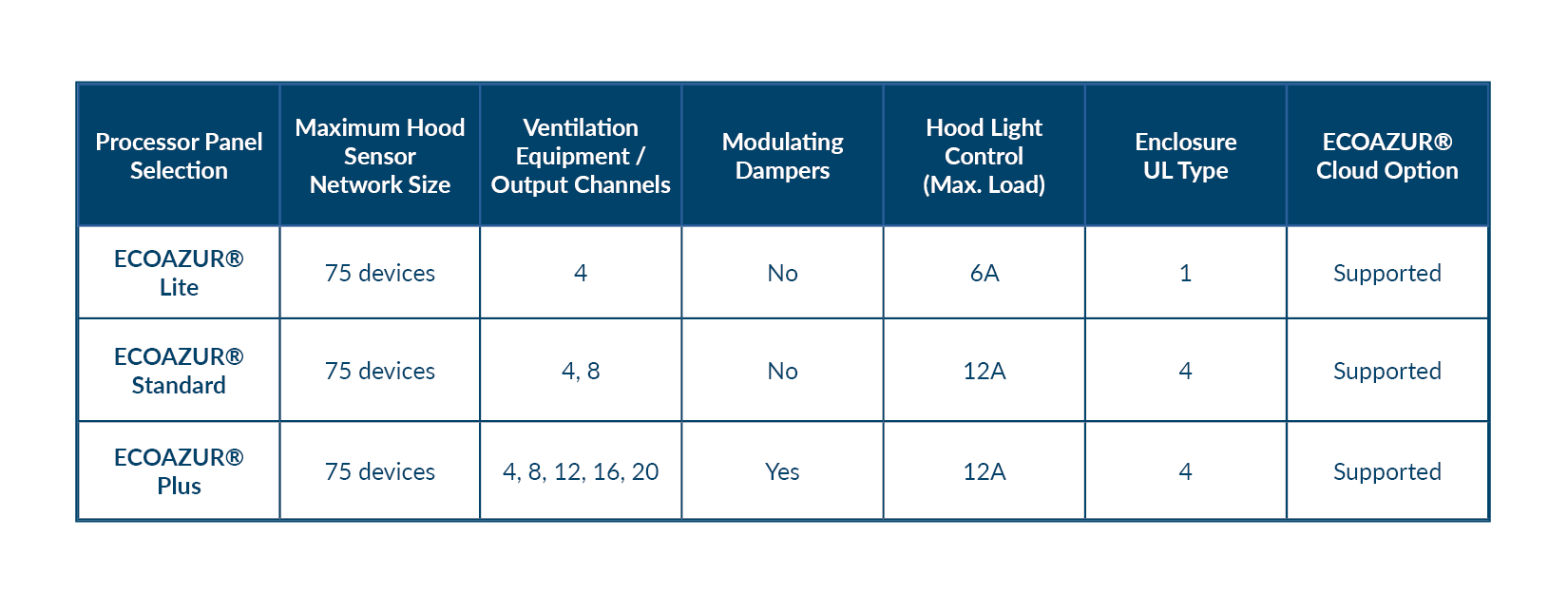

3 energy-saving levels to choose from

Learn more about ECOAZUR®